Robot Rental Comes of Age

Robots-for-hire provides a new way for small manufacturers to automate

Robot rental is becoming popular with both large and small manufacturers. Photo courtesy Hirebotics Inc.

By renting a robot, manufacturers can free up capital expense budgets. Photo courtesy Ready Robotics Corp.

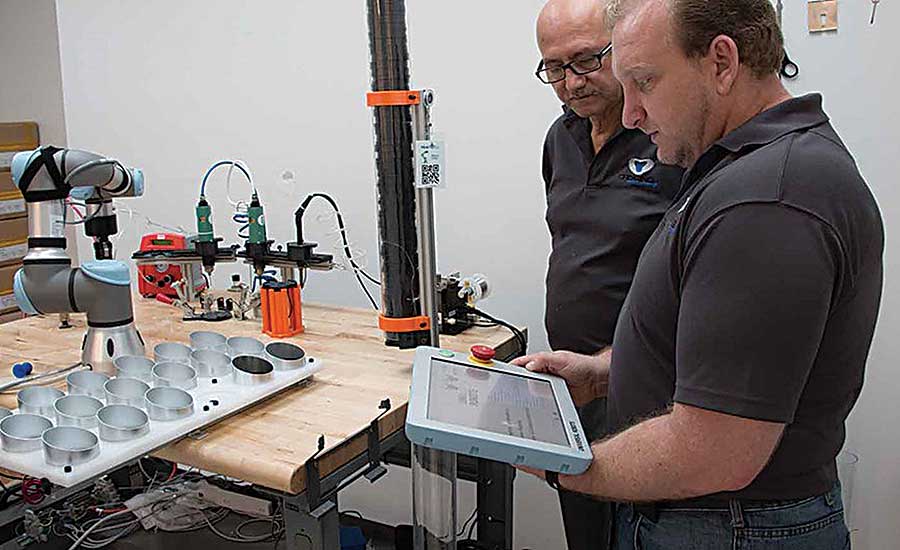

Rental companies act like a staffing agency for robots, handling all programming, deployment and maintenance. Photo courtesy Universal Robots

Traditionally, some manufacturers have avoided robots because of the cost. However, a new robots-for-hire business model is changing that misperception and enabling many types of companies to benefit from automation.

Large and small manufacturers in a wide variety of industries are now beginning to treat robots as “temp workers.” It’s part of a new trend called Robotics as a Service (RaaS).

“RaaS originally was coined to describe the business model whereby robotic platforms functioned on cloud platforms that were sold as a service to end users,” says Rian Whitton, a research analyst at ABI Research Inc. “Now, RaaS represents one of the most notable phenomena in the development and diversification of commercial robots across an ever-expanding list of markets and [applications].”

According to Whitton, several factors are driving the RaaS trend. “One is macroeconomic,” he points out. “There are large labor shortages in markets where there is not a whole lot of technical expertise.

“End users want robotic solutions, but don’t have the know-how to deploy or maintain them,” adds Whitton. “This creates an opportunity for RaaS providers to lease out their robots as a service, and look after maintenance and upgrading, as well as providing data services.

“Then, there are the general technological improvements,” explains Whitton. “On the hardware side, innovations in batteries, sensors, embedded systems, end effectors and robotic platforms have led to the development of robots that can be useful for a range of markets. On the software side, machine learning, cloud and edge-computing, and data analytics enable providers to deliver services beyond hardware, including predictive maintenance and data optimization.”

A Growing Trend

Growing demand for collaborative robots is fueling interest in the robots-for-hire concept. The new generation of machines is ideally suited to performing a wide variety of assembly tasks that can be easily automated, such as adhesive dispensing, screwdriving and soldering. Humans can work safely alongside collaborative robots with minimal safety restrictions.

Demand for rental robots is expected to increase 14 percent annually over the next five years, claims a recent report from Technavio Research.

“Robot rental is going to become much more common in the future,” predicts Matt Bush, cofounder of Hirebotics Inc., which pioneered the concept two years ago. It currently provides a fleet of robots for a variety of manufacturers that use the machines for applications such as assembly, machining tending, parts feeding, parts kitting, test and inspection, and spot welding.

“Robot rental will follow a similar path as the forklift market experienced over the last 20 years,” claims Bush, a mechanical engineer who previously served as director of operations at Scott Fetzer Electrical Group, a manufacturer of small motors that was an early adopter of collaborative robot technology. “Renting is also commonly done with CNC machine tools and construction equipment.

“By renting robots, manufacturers can use their capital for things that make them different and unique in the marketplace,” says Bush. “Robots don’t make you unique—they are just another way to perform human tasks.”

According to Bush, rental is a way for companies to dip their toes in the water with a try-before-you-buy approach. “This enables smaller manufacturers to get a robot in-house and see if it actually makes sense for them to automate workstations or processes,” he explains. “Then, they can always decide to purchase a robot later on.”

Another player in the domestic robot rental market is Ready Robotics Corp. It charges customers a monthly fee for a robotic arm that comes equipped with a mobile base that can be rolled into position anywhere in a plant. Ready Robotics’ customers range from small machine shops to large manufacturers, such as Black & Decker.

“Our robots-as-a-service solution is tough enough to handle real industrial tasks and flexible enough to be deployed in mere hours,” claims Benjamin Gibbs, CEO of Ready Robotics. “[Our] unique combination of plug-and-play tooling and easy programming interface makes the formerly expensive and complicated task of automation achievable for all manufacturers.

“Traditionally, industrial robotics has required a lot of highly customized integration work, with upfront costs typically running several times the cost of the robot arm itself,” says Gibbs. “Even worse, with the process taking weeks, integration gobbled up precious time. Our TaskMate system can be deployed in a matter of hours at a fraction of the cost of traditional solutions.

“Small manufacturers want the same type of robotic automation they see larger manufacturers using, but they don’t want to sacrifice flexibility,” explains Gibbs. “Capital equipment purchases often require a fairly lengthy approval process that can take weeks or months.

“Renting a robot is a much quicker way to address an immediate production need,” says Gibbs. “It’s something that can easily come out of your operating expense budget, while freeing up your capital expense budget.”

Both Hirebotics and Ready Robotics rent collaborative machines produced by Universal Robots (UR), such as the company’s popular UR5 robotic arm, a six-axis device that can handle payloads of up to 11 pounds. However, both vendors eventually plan to offer machines from other suppliers.

In Europe, an Irish company called Innovative Total Solutions (ITS) offers a “rent to buy” scheme. “This innovative way of buying any of our Universal Robots allows you to get up and running without any immediate overhead,” claims Martin Buckley, technical director at ITS. “The rent-to-buy scheme operates through a lease option agreement whereby you agree to rent the robot for a specified period with an option to purchase at a pre-agreed price.

“A small deposit is all you need to go ahead once the agreement is in place,” Buckley points out. “At the agreed purchase date, you have the option of proceeding with the purchase of the robot at the agreed price.”

A British startup company called Bots also rents UR machines. It charges $90 a day for the service.

“We are able to advise the most suitable way to implement the robot into a business, and we offer training and programming upon delivery,” says Tim Warrington, CEO of Bots. “Most clients will start out with one robot to see how it goes, before hiring multiple numbers.”

In Asia, ABB Robotics and Kawasaki Robotics are each involved with third-party firms that rent their collaborative robots.

ABB works with Orix Rentec, a subsidiary of leasing giant Orix. It offers six-month contracts for the YuMi robot, with the option of a 24- or 36-month renewal.

Kawasaki Heavy Industries is partnering with a company called Century Tokyo Leasing, which offers six-month contracts on the duAro robot.

Unique Business Model

Renting robots enables manufacturers to pay for automation the same as they do for temporary workers. There’s no need for upfront costs or huge outlays of capital.

Although automation can help manufacturers increase production and quality while improving efficiency, many small firms are still reluctant to invest in robots. Fear of blowing the budget often eclipses the fear of falling behind.

Companies such as Hirebotics and Ready Robotics are attempting to eliminate those traditional barriers. They act like a staffing agency for robots,

handling all programming, deployment and maintenance.

“We are basically a systems integrator that just has a unique business model,” says Hirebotics’ Bush. “We don’t require customers to purchase capital equipment.

“We provide a full turnkey robotic solution, featuring a robotic ‘worker’ that gets billed out by the work hour,” explains Bush. “It’s no different than if you contacted a temp agency and said ‘I need a person to come in and do this job.’

“We charge customers an hourly rate that’s comparable to what they would be charged by a temp agency,” Bush points out. “It’s typically in the $15 to $20 range, with a minimum of 80 hours a week. The actual cost depends on the complexity of the robotic cell, such as vision systems. It’s a little more in some markets and a little less in others.”

Hirebotics bills to the second. Manufacturers only pay for when actual production takes place. Unlike humans, the robots don’t stop for lunch or take breaks.

“One of our robots operates 22 hours a day at an automotive plant and makes a part every 3 seconds,” says Bush. “There’s no charge for changeover and other times when the robot is not making or handling parts.”

Hirebotics installs a small embedded computer on each robot. Bush and his colleagues communicate with the machines via that device. They can remotely log in and troubleshoot any production issues or problems that occur.

“We are constantly monitoring our robots and collecting data for billing purposes, remote monitoring and diagnostics,” notes Bush. “We provide all sorts of data back to our customers through a mobile app that they can access from anywhere.”

Engineers can gauge the condition of robots in real-time by monitoring parameters such as temperature, CPU load, and the number of hours the robot has been active. This ensures efficient predictive maintenance planning and scheduling. The information collected by continuous monitoring is saved in cloud servers for backup, reporting, diagnostics and benchmarking.

“Our customers range from tiny startups with a handful of employees up to multinational corporations with thousands of employees and hundreds of robots,” says Bush. “In fact, one of our newest customers has multiple assembly cells that already house traditional six-axis robots.

“Large manufacturers, such as Tier One automotive suppliers, don’t have to invest capital in a program that may not be around long enough to justify the investment in additional robots,” explains Bush. “And, they can now justify automating production lines that may support products that are at the tail end of a multiyear vehicle platform.”

One manufacturer that has benefitted from renting robots is Tenere Inc., a contract manufacturer that specializes in sheet metal fabrication and plastic injection molding. The company has been using collaborative robots at its sheet metal facility in Dresser, WI. The machines are used in Tenere’s assembly and press departments.

“We have used automation in our facilities for years, but robotics is new to us,” says Edward Moryn, operational excellence manager at Tenere. “Renting robots enables us to use the technology without the large investment or insecurities that go with purchasing them.

“It allows us to stay current with the new technology, because it’s changing so quickly,” adds Moryn. “If we purchased robots, they would quickly be outdated. It also allows us to be flexible with the ever-changing demands of our customers.”

Tenere’s robots work alongside humans, performing tasks that pose ergonomic hazards.

“The jobs our robots are programmed to complete are very repetitive and potentially dangerous for humans,” says Moryn. “By using robots for these tasks, we reduce fatigue and repetitive strain injury risks for our employees.

“At Tenere, we are creating a symbiotic relationship between robots and humans,” explains Moryn. “Our robots complete extremely repetitive tasks quickly and efficiently, freeing up time for our employees to focus on more important responsibilities.

“A common misconception is that robots are replacing our employees,” Moryn points out. “In fact, they are helping our company ship more products to our customers, because of the efficiency and consistency gains. This allows us to grow and hire even more people.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!