Feeding and Driving Small Screws

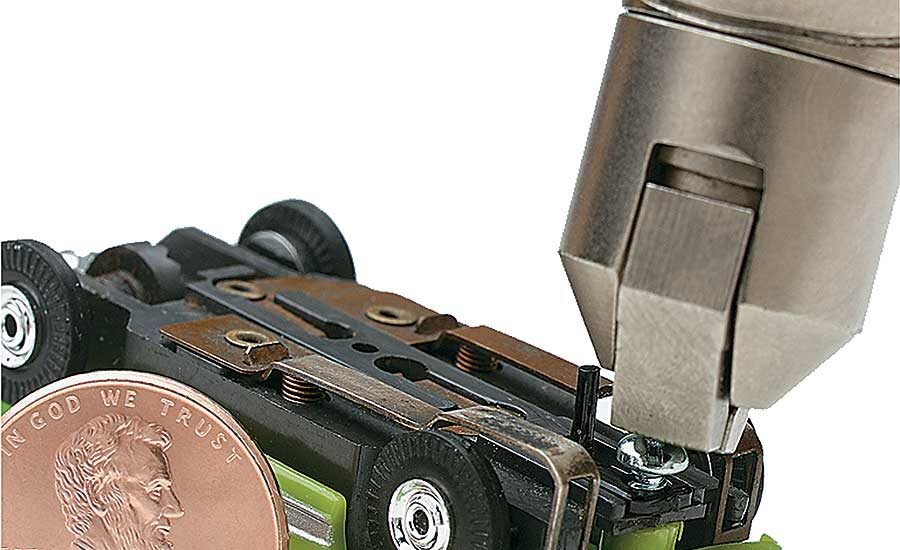

Specialized equipment is needed to feed and drive very small screws.

This small, servo-driven screwdriving spindle was designed specifically to install micro fasteners. Photo courtesy Weber Screwdriving Systems Inc.

Micro fasteners can be as small as 1 millimeter in diameter and as short as 2 millimeters long. Photo courtesy Wei Shiun Fasteners Co. Ltd.

Micro screws are tightened to very small torques—as low as 2.8 in-oz. Photo courtesy Visumatic Industrial Products

Small fasteners can be blow-fed, as long as the length of the screw is at least 1.5 times the head diameter. Photo courtesy Design Tool Inc.

The MINIMAT-EC-Servo screwdriver and AST controller are ideal for installing small screws. Photo courtesy DEPRAG Inc.

A cell phone manufacturer had a problem: Although it was staffed by four assemblers, the screwdriving station had become a bottleneck.

Eight small screws (M1.6, 5 millimeters long) had to be installed in the rear housing of a cell phone. Using a low-torque transducerized DC electric tool with vacuum tooling, an assembler would pick up a fastener from a standard, off-the-shelf screw presenter and install it in the housing.

On the one hand, the operation required some care. Picking up the tiny screws and locating them over the drive points was tricky, and the cell phone case could not be scratched. On the other hand, assemblers had to keep pace with the high-volume assembly line.

“The operators were trying to go so fast, the screws were getting knocked off the vacuum tip, or they were getting crooked on the driver and marring the cell phone case,” recalls Tim Hochkeppel, applications and business development engineer at Visumatic Industrial Products.

To solve the problem, Visumatic designed a system to blow-feed the screws to a handheld driver. To protect the cover, Visumatic developed a hinged overlay that covers the phone during fastener installation. The overlay features bushings at each fastening location to help the operator guide the screw into the hole.

“Now, the operators can go as fast as they want, as hard as they want. They insert the bit through bushing and chase the screw into the drive location,” says Hochkeppel. “This sped up production, decreased labor costs, and protected the product.”

The case of the cell phone manufacturer is illustrative of a trend not just in the consumer electronics industry, but in the medical device and defense industries, as well. As assemblies get smaller, so too, do the fasteners that hold them together. Micro fasteners can be as small as 1 millimeter in diameter and as short as 2 millimeters long. These tiny fasteners are not simply scaled-down versions of larger screws. Feeding and driving them requires specialized equipment.

“We’re talking about #0 screws or lower. You could put five to 10 on the tip of your finger with ease,” says Jim Graham, president of Weber Screwdriving Systems Inc. “These are low-mass, high-precision fasteners. They are very expensive, and they tend to be very short. That creates problems with how you sort them, how you feed them, and how you pick them up. If you had to install these manually, you would need a magnifier and tweezers.”

Feeding Small Screws

When feeding small fasteners or large ones, the ratio of head diameter to overall length is important. Screws with a head-to-length ratio of 1-to-1 will be problematic to feed. Ideally, the length of the screw should be 1.5 to 2 times the head diameter.

In addition, small screws pose challenges that aren’t an issue with larger fasteners. For example, depending on what they’re made of, small screws can become statically charged. As a result, they will often cling to the surface of a bowl feeder or step feeder. A positive ion discharge can mitigate that issue.

Standard bowl feeders running on straight AC power produce 120 vibrations per second on 60 hertz current. That’s too aggressive for very small screws.

To solve that problem, Weber Screwdriving, DEPRAG Inc. and other suppliers of automatic screwdriving technology now offer piezoelectric feeders to feed small screws. For example, Weber’s new ZEP090 Micro Piezo Inline Feeder produces 140 to 400 vibrations per second.

“It gives you much more control over the fasteners, and it’s much gentler on them,” says Graham. “When you touch the bowl, it feels like a soft buzz.”

And, because the fasteners are so small, guide tooling and escapements require narrower tolerances and tighter fits.

“Normally, when you transition from a vibrating component to a static component, like an escapement, we’d have an air gap,” explains Graham. “With micro fasteners, that transition becomes much more problematic. These little tiny components will find a way down into those gaps, so everything must be made at much tighter tolerances.”

Tiny Torque

Not surprisingly, micro screws are tightened to correspondingly small torques. A standard screwdriving operation might require, say, 1 to 3 newton-meters of torque. In contrast, a micro screwdriving application might require as little as 2.8 in-oz.

For small fastener applications, DC electric tools are preferred over pneumatic ones. “Pneumatic tools are good for torque above 2 in-lb, especially if there’s a wide tolerance,” says Hochkeppel. “But, if you need to tighten a screw to 1 in-lb, and your tolerance is 0.1 in-lb, you need a transducerized DC electric tool.

“DC tools also give you the ability to regulate speed. You can start slow, speed up, and slow down to you don’t overshoot your target.”

But, even DC electric tools need to be designed specifically to install small screws. “For micro fasteners, you need much more torque control,” explains Graham. “To get that, you need to reduce the mass of the transmission and the bits. With a high-mass bit, it’s easy to overshoot the torque simply due to the inertia of the drivetrain.”

Tips and Tricks

“You get what you pay for” is good advice for any assembly operation, but it’s particularly true for applications involving small screws. “Purchase good quality screws,” urges Kevin Buckner, director of engineering at Design Tool Inc. “Poor screw quality—partials, flashing, things like that—is an even bigger problem with smaller screws because you have less of margin for error.”

A vacuum sleeve on the end of the tooling will help an assembler retrieve a screw from a screw presenter and keeps the fastener engaged with the bit. It also enables a tool controller to recognize when a fastener has been picked up and when it has been installed.

“Vacuum tooling also removes any particulates that might be on the screw,” adds Graham. “Electronics manufacturers are increasingly asking us to clean the screws in the feeder and during the screwdriving process. Research has shown that even tiny particulates can contaminate a circuit board enough to shorten the life of the product.”

Because inserting a tiny screw in a tiny hole is difficult enough without the pressure of meeting takt times, engineers are well-advised to design features, such as counterbores or scallops, in their parts to help assemblers find each fastening location.

“For a lot of part designers, automation is an afterthought,” says Hochkeppel.

If automatic screwdrivers will be used, engineers are well-advised to provide enough room for the collet and barrel to access each fastening location.

“The No. 1 problem we run into is not having enough space for the automation components,” says Buckner. “The temptation to crowd things is even greater when you’re working with really small screws.

“If the screw is going into a counterbore, we like to have 0.03 inch on a side, but we can’t always get that. At a minimum, we need 0.02 to 0.025 inch on a side,” he adds. “If the screw is being installed next to a wall, we need at least 0.03 inch of space between the head of the screw and the wall. More room is always better.”

If the fastener will be driven in a horizontal location, the tooling needs to get close enough to the workpiece so the screw can engage the pilot hole before the collet releases the screw.

“You can get away with a little more distance if the screw is being installed vertically, but if it’s horizontal, the screw must be engaged before the collet opens, or you will lose control of the fastener,” Buckner says.

How an operator handles the tool can exaggerate errors. “Because the screws are so small, the torque can vary quite a bit if the operator pushes down too hard on the tool or if he comes in a little crooked,” says Cecil Morgan, project manager at DEPRAG.

In fact, because alignment of the driver is so important when installing small screws, equipment suppliers are increasingly recommending robotics for the task. Benchtop Cartesian and delta robots are more affordable and easier to use than ever before.

“We’re doing quite a bit of work on small, lightweight screwdriving tools for collaborative robots, like the UR 3 [from Universal Robots],” adds Graham.

A screwdriving robot is exactly what a manufacturer of safety glasses implemented recently. The manufacturer uses a pair of small screws (M1.6, 6 millimeters long) to attach the two “temples” to the frame. (The temples are the long arms on the sides of the frame that extend over the ears to keep the glasses on the wearer’s face.) The manufacturer was employing six assemblers for this task, with a goal of producing one pair of glasses every 6 seconds.

The eyewear manufacturer contacted Visumatic to see if the task could be automated. Visumatic developed a semiautomatic cell consisting of Cartesian robot equipped with a screwdriving spindle, says Hochkeppel. Now, a single operator simply loads the frames and temples into a fixture and hits the start button. The driver installs each screw to a torque of 0.6 in-lb in just 3 seconds.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!