Home » Keywords: » screwfeeder

Items Tagged with 'screwfeeder'

ARTICLES

New Technology for Automatic Screwdriving

Collaborative robots are among the latest products for automatic screwdriving

February 5, 2020

What’s New With Automatic Screwdriving?

Flexible feed and drive systems improve productivity.

February 5, 2018

advertisement

How to Provide Maximum Processing Reliability on a Manual Screwdriving Workstation

March 8, 2016

Rotary Indexer Assembles Hinges for Car Doors

This eight-station automatic system produces a hinge in less than 10 seconds.

June 3, 2013

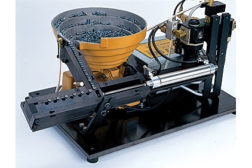

Automation for Small Screws

Tiny fasteners present big problems for assemblers

February 1, 2012

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing