Options for Welding Small Parts

Unlike traditional TIG welding, micro TIG is done under a microscope at very low amperages (less than 10 amps) with fine control of the amperage range. Photo courtesy Micro Tool Welding

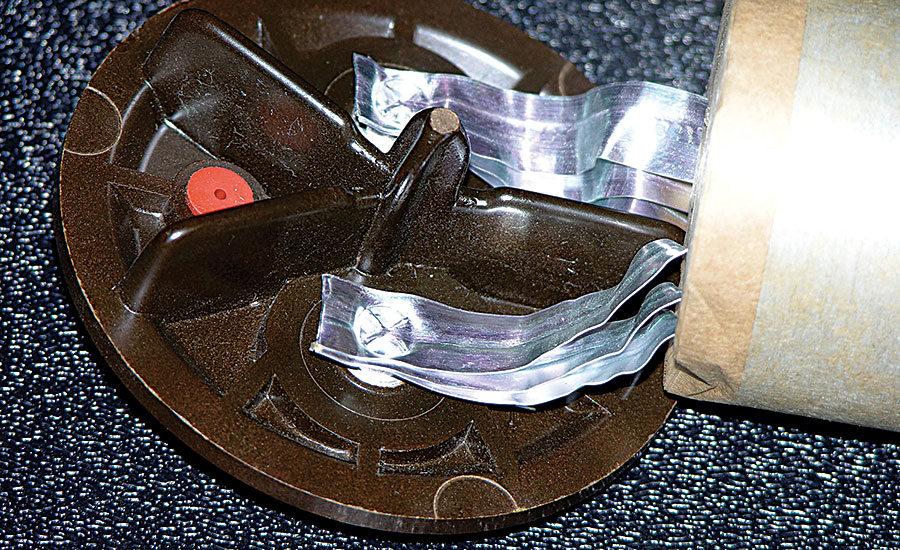

By far the most popular uses of ultrasonic welding over the last 20 years are for sensors and battery tabs (shown spot welded to terminals). Photo courtesy Sonobond Inc.

One aerospace supplier regularly uses inertia friction welding to weld bimetallic airplane rivets. The rivet head is made of high-grade titanium, and the rivet shaft of a lower grade. Photo courtesy Manufacturing Technology Inc.

Ask an engineer for a one-word description about welding small metal parts, and it’s a good bet he’ll reply, “challenging.”

Gary Filer has faced the challenge of welding small metal parts every day since 2003. He is the founder and owner of Filer Micro Welding, which is based in Forest City, NC, and has a staff of eight

welding technicians.

“We weld all types of small metal parts under a microscope,” explains Filer. “It’s extremely precise work that usually can’t be done with a robot or fully automated equipment. Most parts are for medical devices or electronic components used in a wide range of industries.”

For example, one electronic component was welded to an oil well drill head so it can be maneuvered in different directions during drilling. On the medical side, Filer’s company recently welded together a tiny tube (0.05-inch wide) and dowel pin (0.02-inch wide) for a reamer tool that drills into the femur bone during knee-replacement surgery.

“Manufacturers often ask me if I can weld two small parts that I’ve never welded before,” notes Filer. “I tell them the truth, which is maybe, because I still don’t know the full capabilities of micro laser welding.”

For several decades, ultrasonic and resistance welding have been the most common ways to weld palm-sized or smaller parts. Although both these methods remain popular, manufacturers now have other options. One is micro welding. Two others are standard laser welding and friction welding, which have evolved technologically and become cost-effective for this type of work.

Ultrasonic Welding

Ultrasonic energy was first discovered in the late 1950s. Aeroprojects (now Sonobond Inc.) was awarded the first metal welding patent in 1960, and soon after, introduced its first ultrasonic welding system for fine wire. According to Janet Devine, president of Sonobond, semiconductor manufacturers immediately began using this system to weld low-current, tiny wires (less than 0.005-inch wide) to circuits. The system featured a 60-kilohhertz, 12-watt power supply and ultrasonically welded wire in the same manner as standard systems, but without the use of filler metal.

The two surfaces to be welded are held together under moderate clamping force. Mechanical vibrations are then applied parallel to the joint interface, creating a relative motion between the surfaces. This scrubbing motion deforms, shears and flattens local surface asperities, and disperses interface oxides and contaminants to create intimate metal contact between the surfaces and form a solid-

state weld.

Ultrasonic welding can weld a wide range of metals, including copper, aluminum and magnesium, and soft metal alloys such as gold and silver. The process is commonly used in applications involving multiple layers, dissimilar materials and dissimilar thicknesses. Weld cycles are fast, typically under one second, and the process is easily automated. Plus, consumables such as filler metal or shielding gas are not required.

Another advantage is cost. Devine says a tabletop ultrasonic welder for small parts costs less than $30,000, which is less than a friction welding system and much less than a laser welding system. She acknowledges that ultrasonic welding is more expensive than resistance welding, but adds that ultrasonic is more cost-effective.

As for limitations, ultrasonic welding requires access to both sides of the part. Also, joints are typically limited to lap joints, and the thickness that can be welded is limited by the power supply and metal hardness. Tooling requirements are stringent. The tooling must have high hardness to avoid deformation, good toughness to avoid fracturing, and good strength at

high temperature.

Devine says automotive, aerospace, appliance, and medical products and electronics manufacturers use ultrasonic welding extensively. Over the last several years, there has been increased interest in ultrasonic welding for sensors and battery tabs.

Devine notes some other interesting small-part applications: welding a resistance wire to a 1-millimeter-wide element for underfloor heating, joining two 20-gauge wires to a terminal for a water-sprinkler controller, and welding tin-plate bus wire to a nichrome coil for a cigarette lighter.

“Customers don’t always tell us what the parts are for,” admits Devine. “But, because ultrasonic welding generates only momentary and focused heat, it can safely weld explosive stuff. Some customers have ultrasonically welded copper percussion caps for firearms. Others have joined wires to a detonator fuse embedded in pyrotechnic material.”

Resistance Welding

Like ultrasonic welding, resistance welding has a several-decade track record of joining small metal parts quickly and cost-effectively. Both methods also join similar or dissimilar metals.

Where they differ is resistance welding handles both nonferrous and ferrous metals. Small parts can be made of aluminum, brass, copper, nickel, carbon or stainless steel, tungsten and titanium.

In resistance welding, the parts to be joined are pushed together while an electrical current is passed through them for a brief time. The heat for welding comes from resistance to the current, both within and between the parts and electrodes. When the current stops, the electrodes continue to hold the parts together while the metal cools, forming a weld.

Resistance welding requires small amounts of consumables, ensures operator safety (due to low voltage), and is energy efficient, clean and environmentally friendly. As for production, advances in weld head design and closed-loop technology enable throughput of more than 100 welds per minute on small parts.

Resistance welding can be easily automated because the electrodes grip the parts and are, to a certain degree, self-fixturing. Another appeal is a minimum heat-affected zone (HAZ), where weld heat barely alters material at or near the weld. This benefit is important to electronics manufacturers when welding heat-sensitive armatures, connectors, solenoids and small PCBs.

Automotive manufacturers resistance weld small wires, micro switches, battery tabs, bus bars and parts for air bag detonators. Resistance welding small parts also is very common in the aerospace, appliance and medical

device industries.

“For several years, one medical device company has resistance welded very tiny wires to a metal component for a pacemaker,” notes Heinz Bockard, managing director for STRUNK Connect Automated Solutions Inc. “The component is smaller than a dime.”

Tim Frech, senior engineer for EWI, says resistance welding has two negatives: the need to contact the parts with electrodes and the need for heat input that’s greater than laser welding. Capital costs can vary from $10,000 to $70,000, depending on power supply type, weld head design and control capability.

When the two metals to be welded have extremely divergent melting points, manufacturers can use STRUNK’s resistance hard-soldering system, says Bockard. In this system, solder is automatically added to the welding process to minimize the variance of separating forces and achieve high peel adhesion. Solder feeds are closely monitored and equipped with motor-driven unwinders.

To ensure quality welds, control technology on STRUNK’s welding systems uses inverters rather than transformers. Bockard says the inverters better detect when electrodes need replacing (worn, dirty, etc.), use much less power and guarantee optimum process reliability.

Laser Welding

For the last 20 years, laser welding of small parts for the medical and automotive industries has increased dramatically. Geoff Shannon, manager of advanced technology for Amada Miyachi America Inc., says the reason is because laser welding is noncontact, fast (milliseconds), precise and ideal for high-volume applications.

The most popular types of lasers used to weld small parts are ytterbium-fiber, disk (active mirror), Nd:YAG and CO2. Besides the laser power supply, a laser welding system typically features an enclosure, a control unit and optics to focus and deliver the laser beam to the parts to be joined. Depending on the application, the setup might also require a fixture to hold the parts; a cooling system; a nozzle for shielding gas; and an exhaust system to remove any smoke produced during welding.

One key advantage of laser welding is that no force is exerted on the parts during welding, resulting in minimal marking or distortion after welding. Low overall heat input means that welds can be made close to heat-sensitive components without fear of damage.

Finally, laser welding is very flexible. The beam can create a weld in places not accessible to the electrodes used in other welding methods. Also, lasers accommodate butt, lap and fillet joints.

A wide range of metals can be laser welded, including stainless steel, ferrous and precious metals, and alloys. However, some dissimilar metals cannot be laser welded.

“Certain parts, like an air bag initiator, must be laser welded,” explains Shannon. “It contains a thin wire that heats up and penetrates the propellant chamber, which produces nitrogen gas to fill up the air bag. For at least the last 15 years, the wire on every initiator in the world has been laser welded.”

Medical device manufacturers prefer laser welding to resistance or ultrasonic welding because a laser is more precise, notes Shannon. Common laser welding applications of small medical parts include hermetically sealing implantable devices, joining end effector tools to tube bodies, and spot welding catheter coils for balloon or stent placement.

Friction Welding

When it became commercialized in the 1960s, friction welding was used primarily by automotive and aerospace manufacturers to weld large parts such as truck axles, transmission components and jet engine compressor rotors. Suppliers have since been able to scale down their equipment so that friction welding of small parts is more cost effective.

There are two types of friction welding: linear and rotary, with inertia and direct drive being variants of the latter. In rotary welding, one metal component is rotated against a fixed component under pressure. Friction between the two parts (having the same or different diameter) removes surface oxides and heats the metal in the joint zone to the plastic state.

As the parts begin to upset, the metals intermix and bond to each other. The rotation stops and additional axial force is applied, producing an airtight weld that covers the entire joint interface. In linear friction welding, the moving piece oscillates linearly instead of spinning.

For inertia welding, the rotating part is clamped to a flywheel that rotates at a pre-calculated speed to store the energy needed for welding. The flywheel is then disengaged from the machine’s motor. Parts are brought together under axial pressure, and rotation stops naturally as energy from the flywheel dissipates.

The rotating part is clamped directly to the motor for direct-drive welding. As the parts are brought together under axial pressure, metal at the joint interface reaches plastic temperature. The motor is stopped, and forging pressure is applied.

Daniel C. Adams, chief technology officer for Manufacturing Technology Inc., says the main advantages of friction welding are it does not require filler metals, joins both similar and dissimilar metals, and is highly repeatable. The process can join most steels (through-hardened, carbon, stainless, tool) and nonferrous metals (copper, aluminum, nickel alloys, titanium), but not cast iron.

The main drawback of rotary friction welding is that at least one of the parts must be round. The process also leaves flash around the joint circumference that can be sheared or turned off directly in the machine.

Adams says manufacturers use his rotary friction welding equipment to weld parts as small as 4 millimeters in diameter. One automotive Tier 1 friction welds a palm-size Inconel impeller to a 4-inch-long soft steel shaft. Another Tier 1 uses a fully automated process to friction weld air-bag-inflator pressure vessels to manifold caps.

Manufacturing Technology makes several sizes of friction welding machines. Adams says that the Model 40 inertia friction welding system, which applies up to 500 pounds of pressure, is best suited for small metal parts. One aerospace supplier regularly uses this system to weld bimetallic airplane rivets. The rivet head (the stationary part) is made of high-grade titanium, and the rivet shaft (the rotating part) is of a lower grade.

Micro Welding

Laser and TIG welding can be performed at the micro level using a high-powered microscope (10X to more than 20X). According to Filer, micro laser welding is becoming more popular, while micro TIG is in decline because it creates a much larger HAZ near the weld.

Micro laser welding, like the standard process, is computer controlled. But, it only uses fiber-optic lasers. Besides welding small parts, the micro laser process can perform cylindrical welds and fabricate tubular assemblies.

One of Filer’s more challenging recent micro laser welding projects required him to weld 0.01-inch-wide stainless steel wire to a 0.03-inch-wide rare earth magnet. He also has welded 0.0004-inch wires together and taught a five-axis robot to repetitively weld many prototypes of a tiny medical part.

As with traditional TIG welding, micro TIG requires the application of electric current to the part at the point of the arc gap. There, a molten pool is established and filler rod is introduced into the pool. But, unlike traditional TIG, micro TIG is done at very low amperages (less than 10 amps) with fine control of the amperage range.

“Micro welding has a deadline, but not a set time limit,” concludes Filer. “Every application is different. It may take a few seconds, or several hours over many days.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!