Home » Publications » Assembly eMagazine

Assembly eMagazine

2020 January

Cover Story

Back to TopThe Hubble Space Telescope launched a new age of astronomy, but assembly snafus nearly created a techno turkey

Read More

Features

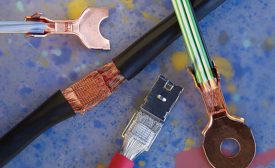

Back to TopMonitoring Activity During Wire Harness Assembly

New technology helps engineers gather real-time data on manual assembly processes, such as wire harness assembly.

January 14, 2020

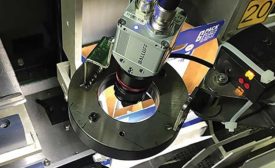

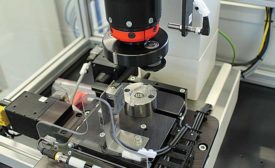

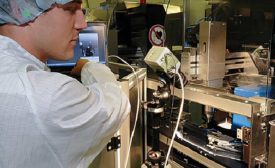

Assembling Fiber Optics

Optical fiber is less finicky today, but it’s still challenging to attach

January 15, 2020

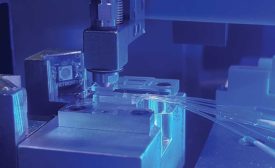

The Appeal of Piezo Jet Valve Dispensing

For applications requiring high speed and precision, cutting-edge piezo jet valve dispensing technology is the way to go

January 9, 2020

Roller Forming for Cylindrical Assemblies

The Roller Forming Process Forms a Curl or Lip on the Edge or Rim of a Hollow, Cylindrical Part

January 8, 2020

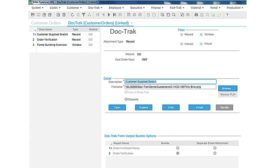

Best Practices for Transitioning from Design to Assembly in Medical Device Manufacturing

Design Transfer Can Ensure a Smooth Product Development Process

January 7, 2020

Columns

Back to TopNever miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing