Home » Keywords: » rotary indexer

Items Tagged with 'rotary indexer'

ARTICLES

Sponsored Content

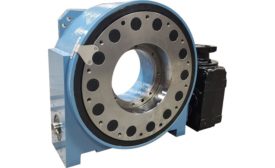

Pick and Place Unit Rotary Indexers for Small Part Handling

February 15, 2024

Sponsored Content

Gearheads vs. Programmable Index Drives for Horizontal Rotation Applications

February 1, 2024

What’s New With Rotary Indexers

Servo indexing and flexibility drive numerous assembly applications.

November 6, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing