Home » Keywords: » mixed material joining

Items Tagged with 'mixed material joining'

ARTICLES

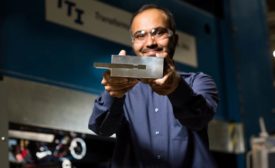

New Techniques for Joining Steel and Aluminum

Lightweighting is forcing automotive engineers to explore cutting-edge technology.

April 11, 2017

Resistance Spot Riveting

A new joining method for sheet metal combines traditional riveting with resistance spot welding.

January 5, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing