Home » Keywords: » photoelectric sensor

Items Tagged with 'photoelectric sensor'

ARTICLES

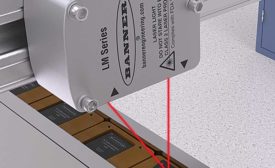

Laser Sensors and Automated Assembly

Very accurate and super fast, these noncontact sensors are ideal for various measurement, inspection and defect-detection applications

June 6, 2019

What’s New With Sensors

New technology is helping to make sensors smaller, more robust and easier to integrate.

June 3, 2016

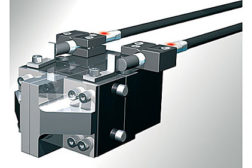

Sensors for Automated Assembly

The typical multistation automated assembly system is equipped with myriad sensors.

June 3, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing