Home » Keywords: » dispensing two-part materials

Items Tagged with 'dispensing two-part materials'

ARTICLES

Automation can help cut costs and improve operating efficiency.

Read More

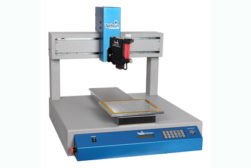

Dispensing and Curing

Automated Dispensing, Curing Technology Saves Money, Boosts Quality

January 13, 2017

New Mixer Optimizes Adhesive Performance

An innovative, square-shaped static mixer conserves two-component materials, speeds curing, and enhances bond strength.

January 6, 2017

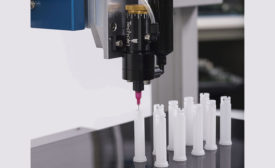

Dispensing Thick Materials

Precise valves and powerful pumps are essential to properly dispense one- and two-component high-viscosity materials.

January 5, 2017

Adhesive Dispensing & Curing

New Dispensing, Curing Technology Improves Productivity

February 9, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing