Home » Keywords: » rotary indexing dial

Items Tagged with 'rotary indexing dial'

ARTICLES

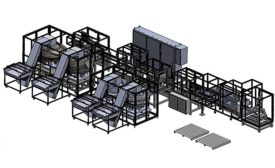

Auto parts, plumbing products and medical devices are among the myriad items made on automated assembly systems

Read More

Fixed vs. Flexible Automation Systems

Both fixed and flexible technologies offer distinct advantages, but only if manufacturers optimize important operational parameters.

September 8, 2017

Automated Assembly Cells

Standardized, preconfigured automated assembly cells can lower costs and reduce time to market.

March 1, 2017

Rotary Indexer Assembles Hinges for Car Doors

This eight-station automatic system produces a hinge in less than 10 seconds.

June 3, 2013

Indexing Dial Fills, Assembles Beverage Caps

Before snapping the parts together, the system dispenses liquid or powdered ingredients into the assembly.

April 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing