Home » Keywords: » design software

Items Tagged with 'design software'

ARTICLES

ASSEMBLY Audible September In-Review

AI, Economy, and the Future Workforce in Manufacturing

October 7, 2024

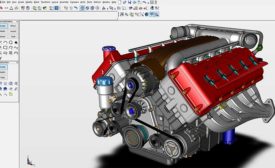

CAD Software Aids Assembly

Next-gen CAD software lets engineers design a part or subassembly, then use simulation to create a virtual prototype of the final product.

March 11, 2021

Harness Design at Nordex

Software aids design and assembly of control cabinets and wire harnesses for wind turbines

October 16, 2020

Five Digital Transformation Failures and How to Avoid Them

Up to 70 percent of digital transformations fail: Don’t be one of them

May 15, 2020

Software Aids Harness Design at Porsche

To manage the increasing complexity of vehicle electrical systems, Porsche relies on object-oriented, database-driven design software.

October 19, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing