Home » Keywords: » orbital and radial forming

Items Tagged with 'orbital and radial forming'

ARTICLES

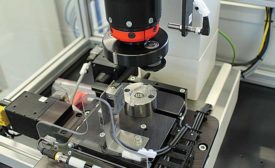

Forming and Riveting

The machine offers a stroke adjustment of 0.01 millimeter with a mechanical system.

Read More

Solutions for Small Rivets

With a shank diameter of 0.138 inch or less, small and micro rivets are ideal for assembling medical devices, PCBs, hand tools and many other products.

August 3, 2022

Fastener Case Studies

These success stories show why screws, pins, rivets, inserts and specialty nuts are among manufacturers’ favorite fasteners for assembling products.

June 8, 2022

Roller Forming for Cylindrical Assemblies

The Roller Forming Process Forms a Curl or Lip on the Edge or Rim of a Hollow, Cylindrical Part

January 8, 2020

What's New With Orbital and Radial Forming

Reliable for 50-plus years, today’s orbital and radial forming machines also offer flexibility, traceability and servo-driven precision

August 6, 2019

Fastening or Pressing of Medical Devices

For a wide range of medical devices, fastening or pressing is often the best assembly method

May 1, 2018

Orbital and Radial Forming for Delicate Assemblies

New technologies are enabling orbital and radial forming equipment to tackle sophisticated assembly applications.

August 4, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing