Home » Keywords: » part marking

Items Tagged with 'part marking'

ARTICLES

New technologies are helping assemblers keep track of product on the line.

Read More

What’s New With Labels and Label Printers

Durable materials and proven printing methods ensure a high-quality label for any size part.

August 5, 2021

Code Marking Considerations

Production volume, durability, substrate and total cost of ownership are among many factors to consider when choosing a part marking technology.

December 12, 2017

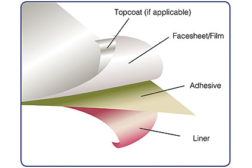

Five Steps to Picking the Best Label

The answers to these five questions will help you pick the perfect label for your application.

March 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing