Home » Keywords: » motor assembly

Items Tagged with 'motor assembly'

ARTICLES

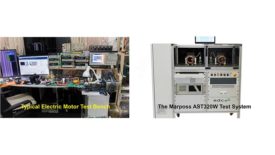

Assembling Electric Vehicle Motors

Engineers are scrambling to find cost-effective ways to mass-produce EV motors.

May 20, 2021

Behind the Scenes at DeWALT

DEWALT’s assembly plant in Charlotte, NC, produces high-quality tools while beating overseas competition.

June 7, 2017

Automated system assembles stepper motors for Tier 1 supplier

Tray handlers and cam-driven assembly cells produce a stepper motor every second.

July 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing