Home » Keywords: » wire termination

Items Tagged with 'wire termination'

ARTICLES

TE’s New Terminal Design Reduces Insertion Force

Liteforce design helps address the conflict between technological requirements and assembly ergonomics

July 12, 2018

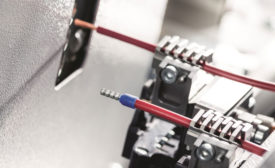

Best Practices in Crimp Applicator Maintenance

Schleuniger recommends preventative maintenance and proper setup to ensure crimp quality

April 11, 2018

Automatic Cut, Strip and Crimp Machines

Advanced servo technology ensures quick machine setup, precise wire processing and high production.

January 6, 2017

The Impact of the LV 214-4 Standard

A new standard developed by German automotive OEMs provides insight into crimp force monitoring.

January 6, 2017

advertisement

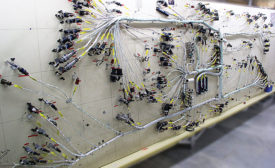

How To Select and Install M85049/128 Shield Termination Bands Onto Wire Harnesses

March 7, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing