John Sprovieri

John has been with ASSEMBLY magazine since February 1997. John was formerly with a national medical news magazine, and has written for Pathology Today and the Green Bay Press-Gazette. John holds a B.A. in journalism from Northwestern University, Medill School of Journalism.

ARTICLES

Wire Harness Assembly: Business Outlook

Harness assemblers took a hit in 2020, but the economic forecast for 2021 looks better.

April 20, 2021

Training for Wire Harness Assembly

WHMA and IPC have developed a new training program for workers who are new to wire harness assembly.

April 16, 2021

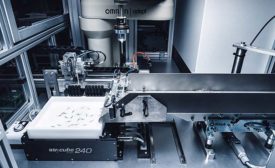

Flexible, Robotic Cells Automate Back-End Assembly Processes

Microfactories combine software, machine learning, machine vision and robotics to create intelligent assembly lines.

March 15, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing