Electrification

Leak Testing Batteries

A new technology accurately tests cylindrical, prismatic and pouch cells for electric vehicles

October 1, 2020

Accelerating electric drive

Navigant says that plug-in electric vehicle sales last year doubled in North America, and sales in Europe and China increased 39% and 77%, respectively. And by 2030, annual PEV sales are estimated to be between 15% and 32% of the global light-duty vehicle market.

September 14, 2020

Tipping point?

Battery electric vehicles could be on the fast track to reach an installed base of over 100 million by 2029, but much of the growth in electrification hinges on battery technology as well as educated and willing consumers.

September 11, 2020

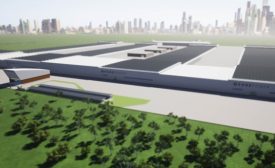

Electric Vehicle Startups Ramp Up Production

Not since the early 20th century has the U.S. automotive industry seen so many startups

March 3, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing