Autonomous & Electric Mobility

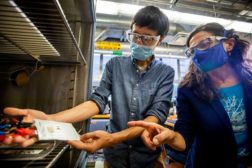

Welding Large-Diameter Cable

Joining the large conductors used to quickly charge electric vehicle batteries will require a new and more reliable approach to ultrasonic welding.

October 12, 2021

Electric Vehicle Manufacturers Explore 3D Printing

Fast Radius Sees Printed Parts as Key to Successful EV Manufacturing

September 29, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing