Featured on Home Page

Some 270 exhibitors will display the latest technologies at this year’s ASSEMBLY Show.

Read More

Maintaining Control in Vertical Ballscrew Applications

A spring-engaged, air-released servomotor brake can prevent back-driving of a ballscrew in vertical motion applications.

October 3, 2016

Adhesives for Speaker Assembly

Light-curing adhesives can help speaker manufacturers increase efficiency.

October 3, 2016

2016 Assembly Plant of the Year: Bosch Rexroth Flexes Its Lean Production Muscle

High-mix lines and continuous improvement drive growth in Fountain Inn, SC.

October 1, 2016

Joining choices: welds, fasteners or adhesives?

No matter which method is used, the goal is low production costs and a quality end product.

October 1, 2016

New Technology for Robotic Welding

A new generation of robots is helping assem-blers weld parts better, faster and more cost-effectively.

September 8, 2016

Innovative Conveyors Maximize Use of Space

New conveyor technologies are giving plant managers more options to make better use of existing space.

September 8, 2016

Troubleshooting Adhesive Bonding Issues

When a bonded joint fails, the problem is rarely with the adhesive.

September 8, 2016

Cordless Tools Improve Quality and Ergonomics at Golf Cart Assembly Plant

Smart cordless tools help golf cart manufacturer Club Car ensure quality and operator safety.

September 8, 2016

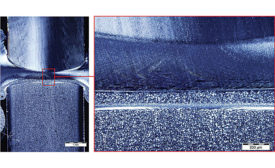

Welding Incompatible Thermoplastics

Incompatible thermoplastic polymers can be welded by using polymer blends that are compatible with both components.

September 8, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing