Electronics Assembly

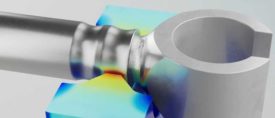

Magnetic Pulse Welding for EV Assembly

The electric vehicle revolution is generating new interest in an old technology: magnetic pulse welding.

July 12, 2023

Robotics

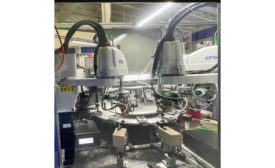

SCARA Robots Solder Circuit Assemblies

Electronics assembler’s DIY automation project saves money and increases efficiency.

May 8, 2023

Manufacturing Software

Johnson Controls and LeanDNA Build Digital Thread

Software connects 14 manufacturing sites and more than 800 suppliers.

April 27, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing