Special Reports

Wearable devices help build better tractors in Jackson, MN.

Read More

Special Report: State of the Profession Report 2017

Digital tools and smart technologies spark a new era in manufacturing.

July 5, 2017

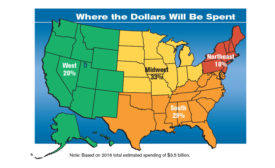

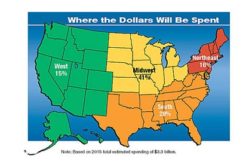

ASSEMBLY Capital Spending Report: Capital Spending to Increase

With automotive and aerospace manufacturing going strong, our annual Capital Equipment Spending Survey predicts continued growth in investment.

December 1, 2016

2016 Assembly Plant of the Year: Bosch Rexroth Flexes Its Lean Production Muscle

High-mix lines and continuous improvement drive growth in Fountain Inn, SC.

October 1, 2016

Special Report: State of the Profession 2016

New tools and technologies help level the playing field.

July 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing