Assembly in Action

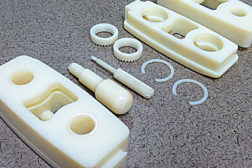

Disc Springs Come Through in the Clutch for DeWalt

The custom spring costs just a few pennies more than the original spring.

October 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing