Wire Processing Assembly

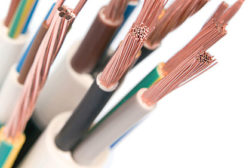

Copper Strikes Back!

New, high-strength copper alloys enable automakers to use thinner wires in their harness designs.

April 1, 2013

Assembling Motors and Bearings at Baldor

Baldor benefits from investing in U.S. assembly operations.

April 1, 2013

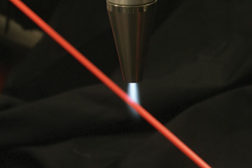

Improving Printability of Wire and Cable

By raising surface polarity, atmospheric plasma treatments optimize the adhesion properties of insulation materials.

April 1, 2013

Handheld Crimping Tools

Hand tools are ideal for prototyping, repair and small production runs.

April 1, 2013

Reborn Company Reshores Harness Manufacturing Jobs

From the 1960s through the 1990s, business was humming at Northwest Regulator Supply in Portland, OR.

March 1, 2013

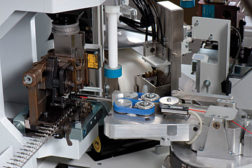

Wire Processing

Should You Invest in Fully Automatic Stripping and Crimping Machines?

if you need to produce thousands of identical crimped wires in a shift, you need a fully automatic cutting, stripping and crimping system.

January 3, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing