Plastics & Metal Welding Assembly

Cobot Welder Boosts Output Tenfold

A manufacturer of exhaust components had nearly given up trying to automate complex, manual welding processes—until it found cobots.

July 6, 2023

Semiautomatic Welding Cells

Not all welding applications need to be fully automated.

June 26, 2023

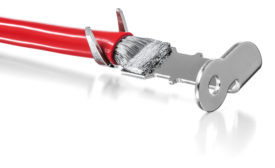

Ultrasonic Welding of Copper Foils for EV Battery Assembly

Ultrasonic welding is a viable alternative to resistance welding and laser welding for joining copper foils in ev battery cells.

June 14, 2023

Inside GE Appliance's State-of-the-Art Water Heater Assembly Plant

A factory that used to mass-produce refrigerators now assembles water heaters.

May 1, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing