Plastics & Metal Welding Assembly

2017 Assembly Plant of the Year: AGCO Leads the Field With Lean Technology

Wearable devices help build better tractors in Jackson, MN.

October 4, 2017

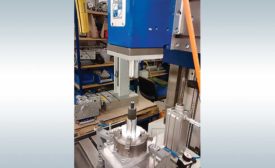

Flexible Assembly Machine Combines Multiple Plastics Joining Processes

What if one machine could be configured to perform any friction-based welding process with a simple change of tooling?

September 12, 2017

Joining Wire to Small Metal Parts

State-of-the-art welding and soldering equipment ensure that wires are securely joined to terminals or other wires.

July 5, 2017

Plastic Machine Components Can Boost System Speed

By upgrading gears, cam followers, track rollers and other components, engineers can improve the speed of a machine by 15 to 20 percent or more.

June 7, 2017

Assembling Thermoplastic Composites

Joining thermoplastic composites—either to each other or to other materials—can be challenging.

June 7, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing