Plastics & Metal Welding Assembly

Agile Automation System Assembles Automotive Inverters

The flexible system can produce three variants of the product

November 5, 2019

Optimizing Ultrasonic Plastic Welds

This advice should assist you in solving day-to-day ultrasonic welding challenges

October 2, 2019

Virtual Templating with Laser Projection

Laser projection allows companies to speed up welding processes, minimize the use of templates and tools, eliminate errors, and improve quality

September 12, 2019

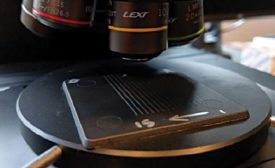

Joint Design for Ultrasonic Welding

These tips will help you design plastic parts for optimal assembly with ultrasonics

September 6, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing