Screwdriving and Riveting Assembly

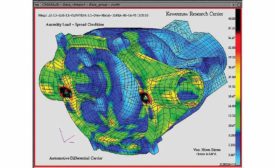

Analyzing Bolted Joints for Clamp Load and Joint Stress

Bolts generate a lot of clamp load in a small area. That’s good for tight joints, but it can also create stress.

April 10, 2017

Driving Thread-Cutting and Thread-Forming Screws

With the proper torque, these fasteners create mating threads in the base material and generate adequate tightness in the joint.

February 2, 2017

Screwdriving & Riveting

New Technology Ensures Error-Proof Fastening

Some 40 suppliers of screwdriving, nutrunning and riveting tools displayed their latest technologies at the 2016 ASSEMBLY Show.

January 10, 2017

Resistance Spot Riveting

A new joining method for sheet metal combines traditional riveting with resistance spot welding.

January 5, 2017

ASSEMBLY Capital Spending Report: Capital Spending to Increase

With automotive and aerospace manufacturing going strong, our annual Capital Equipment Spending Survey predicts continued growth in investment.

December 1, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing