Automated Assembly Systems

The ASSEMBLY Show Preview

Some 200 exhibitors will display the latest technologies at this year’s ASSEMBLY Show.

October 3, 2014

Simplifying integration of peripheral devices

MotionWorks will be able to work with HMIs from several widely used vendors.

October 2, 2014

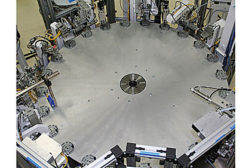

Rotary vs. Linear Indexing

Suppliers complement their cam- and servo-driven systems with newer technologies like direct-drive indexers and precision-link conveyors.

September 3, 2014

Producing in Synch With Sales

Manufacturers have two opposite ways of equipping factories to respond quickly to customer demand.

August 5, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing