Automated Assembly Systems

Flexible, Robotic Cells Automate Back-End Assembly Processes

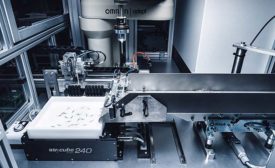

Microfactories combine software, machine learning, machine vision and robotics to create intelligent assembly lines.

March 15, 2021

How Automation Accelerates Reshoring—Part 2

February 9, 2021

Automatic Screwdriving Opens Window to Productivity

A systems integrator, a motor manufacturer and a screwdriving supplier collaborate to increase productivity and quality at ROMA.

February 5, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing