Medical Devices Assembly

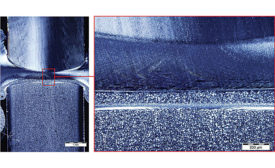

Welding Incompatible Thermoplastics

Incompatible thermoplastic polymers can be welded by using polymer blends that are compatible with both components.

September 8, 2016

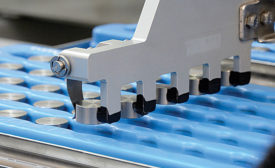

Bullet-Proof Automated Assembly

A system that runs like clockwork doesn’t happen by accident.

September 8, 2016

What’s New With Servo Presses

Needing more precision, energy efficiency and traceability data from their assembly presses, manufacturers are increasingly turning to servo-driven models.

September 8, 2016

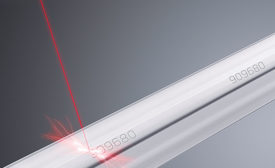

Lasers for Marking Parts

When the application calls for a high volume of parts to be permanently marked, a laser-based system is the best choice.

August 4, 2016

Orbital and Radial Forming for Delicate Assemblies

New technologies are enabling orbital and radial forming equipment to tackle sophisticated assembly applications.

August 4, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing