Automotive Assembly

Here are some tips, tricks and suggestions for using threaded fasteners to assemble plastic parts

Read More

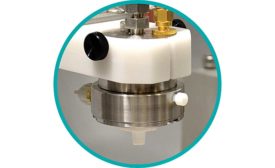

New Process Welds Clear Plastic Parts

Clear polymer materials can be successfully bonded with a new process that combines simultaneous through-transmission infrared laser welding with precision ultrasonic spray deposition technology

April 6, 2020

Pandemic Disrupts U.S. Manufacturing

At best, the pandemic has been an inconvenience. At worst, it has led to part shortages and plant shutdowns

April 2, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing