Aerospace Assembly

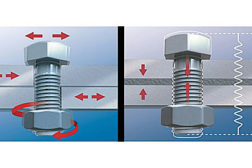

Fasteners vs. Vibration

Manufacturers rely on specialty bolts, nuts and threadlockers to keep fasteners tight and immune to vibration.

October 3, 2014

Automation Helps Productivity Take off at Boeing

Sophisticated motion control systems ensure safety and productivity on the Dreamliner assembly line.

October 3, 2014

Pratt & Whitney Rethinks Jet Engine Assembly

An innovative product requires a new production philosophy.

September 3, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing