Industries

Simulation and analysis software improves 3D-printed structures for Urwahn Bikes.

Read More

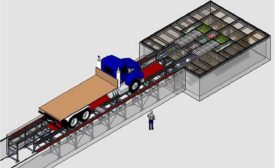

Conveyor Case Studies

With the right conveyor, manufacturers can greatly improve their assembly, part feeding and packaging processes.

July 15, 2022

New Technology for Bonding Automotive Displays

Next-generation interiors demand adhesives that provide optical clarity, structural integrity and thermal interface.

July 11, 2022

VW and the Cloud

By creating an industrial cloud, VW hopes to improve systemwide productivity by 30 percent.

June 30, 2022

Smart Manufacturing at Audi

Digital transformation is well underway at Audi’s five assembly plants worldwide.

June 29, 2022

Industry 4.0 at Škoda

Digital twins, autonomous mobile robots and AI are some of the cutting-edge technologies helping European automaker Škoda compete.

June 28, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing