Industries

Vertical integration once thrived at Ford’s legendary manufacturing complex.

Read More

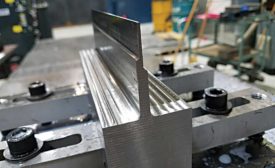

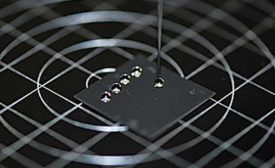

Ensuring Adhesion for Medical Device Assembly

There are many factors to consider when adhesives are used to join hard-to-bond plastics.

March 12, 2019

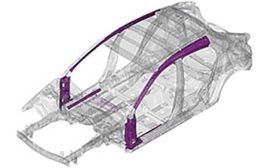

Automakers Turn to Production-Ready Printable Parts

Automotive engineers are bullish on additive manufacturing technology.

March 7, 2019

Smart Appliances and a Future of Interoperability

Data communications standards can enable appliance manufacturers to achieve robust growth.

March 1, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing