Industries

What’s New With Power Tools

Data collection and ergonomics are driving development of next-gen fastening tools

June 5, 2019

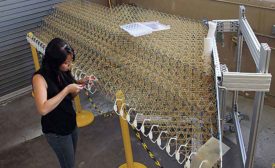

Carbon-Fiber Composites Grow in Popularity

Adhesives and fasteners can be used to assemble many types of composite parts

June 3, 2019

IoT Promises a Future of Guaranteed Outcomes

Smart homes and autonomous driving will be built within ecosystems

May 15, 2019

Workforce Development in the Era of Industry 4.0

Industry 4.0 will change how we define manufacturing work

May 14, 2019

Generative Design Software Is Transforming the Design Process

Aided by cloud computing and artificial intelligence, generative design software is promising to transform the design process

May 13, 2019

America’s Most Destructive Industrial Fire

When an inferno destroyed General Motors’ transmission factory in Livonia, MI, it plunged the automaker into a monumental crisis.

May 8, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing