Home » sensors for automation

Articles Tagged with ''sensors for automation''

Sponsored Content

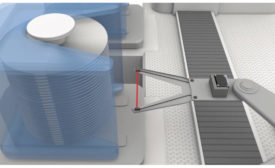

Triangle Package Machinery reduces bagger footprint by 60%

IO-Link increases efficiency and reduces machine footprint

March 29, 2022

Sponsored Content

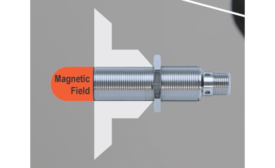

Sensor Technologies to Detect Pneumatic Cylinder Position

March 29, 2022

Sponsored Content

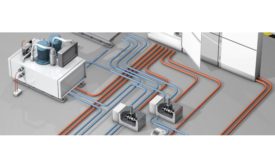

Add Safety and Accessibility With Remote Amplifiers

Why did the sensor cross the road? To work remotely, of course.

March 29, 2022

Sponsored Content

Food for Thought: Should a Fork Sensor be Your First Choice?

December 20, 2021

Sponsored Content

Flush, Non-Flush, or Factor 1? Which Inductive is Best for Your Application?

December 20, 2021

Sponsored Content

Improve the Reliability of Hydraulic Cylinder Position Sensors

March 1, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing