Home » artificial intelligence

Articles Tagged with ''artificial intelligence''

Sponsored Content

AI-Based Visual Inspection for Spark Plug Manufacturing

Digitize and automate visual inspection and traceability for improved quality control and increased productivity.

January 11, 2024

Sponsored Content

The Indispensable Role of Humans in Manufacturing

How AI is Revolutionizing Automation, but Humans Remain the Heart and Soul of Production

January 11, 2024

Robotics

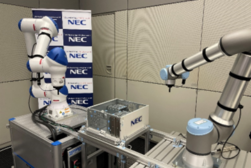

Multiple AI Models Help Robots Execute Complex Plans

A multimodal system uses models trained on language, vision and action data to help robots develop and execute plans for household, construction and manufacturing tasks.

January 9, 2024

Sponsored Content

Product Tracking and Quality Control for Mission-Critical Components

October 19, 2023

Sponsored Content

AI Visual Inspection and Classification for Industrial Part Replacements

October 19, 2023

Sponsored Content

Pleora Adds New AI Inspection and Checklist Capabilities to Vaira Manufacturing Platform

October 19, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing