Home » Industrial Internet of Things (IIOT)

Articles Tagged with ''Industrial Internet of Things (IIOT)''

How can a manufacturer ensure its IIoT assembly lines are properly connected? Use control- and field-level automation equipment with interfaces that meet the latest communication standards.

Read More

Computer Hardware for Industry 4.0

New types of hardware will be needed to collect, route, process and display manufacturing data.

August 18, 2022

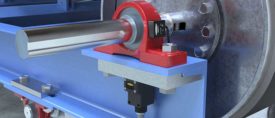

The Power of Predictive Maintenance

Sensors and AI-based software help manufacturers eliminate unplanned equipment downtime.

June 24, 2022

What’s New From the ASSEMBLY Show

In-person trade show provides thousands of engineers with key insights into smart manufacturing, evolving technologies and state-of-the-art tools for assembly.

December 6, 2021

Seven Ways Lean Can Evolve

The future of lean lies in digital manufacturing.

September 2, 2021

How IoT Can Lead to Safer Manufacturing

IoT-enabled devices can alert management to worker fatigue, strain or risk-taking behavior.

August 26, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing