Home » epoxies

Articles Tagged with ''epoxies''

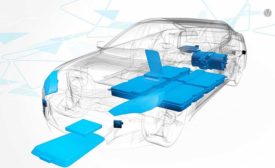

Electric vehicle applications are driving demand for automated equipment.

Read More

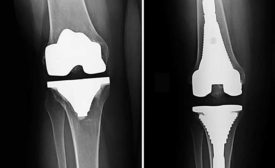

Find the Right Medical Adhesive

Answer these five basic questions to select the ideal adhesive for your medical application.

May 1, 2018

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing