Home » vibratory bowl feeder

Articles Tagged with ''vibratory bowl feeder''

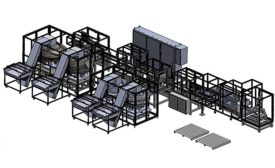

Automated Assembly System Roundup

Auto parts, plumbing products and medical devices are among the myriad items made on automated assembly systems

October 4, 2019

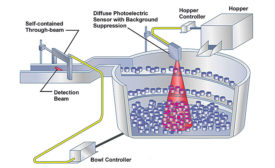

Feeders for Medical Device Assembly

From vibratory bowls to shaker tables, medical device engineers have many options for feeding parts to automated assembly systems.

May 1, 2018

Feeding Nuts and Unconventional Fasteners

Custom design and advanced technology enable feeders to handle a wide range of threaded, nonthreaded and odd-shaped fasteners.

July 1, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing