Home » self-piercing rivets

Articles Tagged with ''self-piercing rivets''

Injection Lap Riveting

A new process, injection lap riveting, is showing promise for joining dissimilar metals.

August 3, 2021

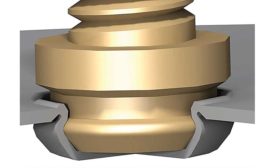

New Developments in Self-Pierce Riveting

New technology incorporates the advantages of self-pierce riveting while overcoming its limitations.

January 6, 2021

Advances in Self-Piercing Riveting

Self-piercing rivets are helping automakers assemble aluminum and high-strength steel

August 2, 2018

Fasteners for Automotive Lightweighting

Hybrid welding-fastener processes join self-piercing riveting as the best technologies for automotive lightweighting.

October 17, 2017

Resistance Spot Riveting

A new joining method for sheet metal combines traditional riveting with resistance spot welding.

January 5, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing