Home » collaborative robots

Articles Tagged with ''collaborative robots''

How to Effectively Deploy Cobots

Assemblers could be throwing away as much as $90,000 per year due to improper integration of collaborative robots

July 15, 2019

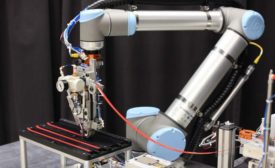

Additive Manufacturing: The Quest for Automation

Robots and other tools are key to mass-producing printed parts

July 9, 2019

New Robots, Grippers Unveiled at Automate 2019

The 2019 Automate Show in Chicago featured the latest technologies in robotics, vision and motion control

May 9, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing