Home » Cartesian robot

Articles Tagged with ''Cartesian robot''

New & Noteworthy

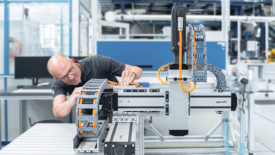

Pick-and-Place Module for Long Strokes With Short Cycle Times

November 9, 2023

The Role of Vision in Robotic Dispensing

Vision-guidance can improve the speed and precision of robotic dispensing processes

May 7, 2020

Small Robots Play a Big Role in Automation

Compact tabletop machines are becoming more popular with manufacturers

April 2, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing