Home » aerospace automation

Articles Tagged with ''aerospace automation''

2013 Assembly Plant of the Year

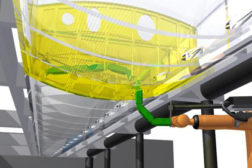

Northrop Grumman Soars With Automation

The robotic Integrated Assembly Line in Palmdale, CA, revolutionizes how airframes are built.

October 1, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing