Home » electric motor manufacturing

Articles Tagged with ''electric motor manufacturing''

Behind the Scenes at Renault’s New Electric Motor Line

Renault has inaugurated a new, highly automated line to assemble EV motors at its historic factory in Cléon, France.

August 7, 2023

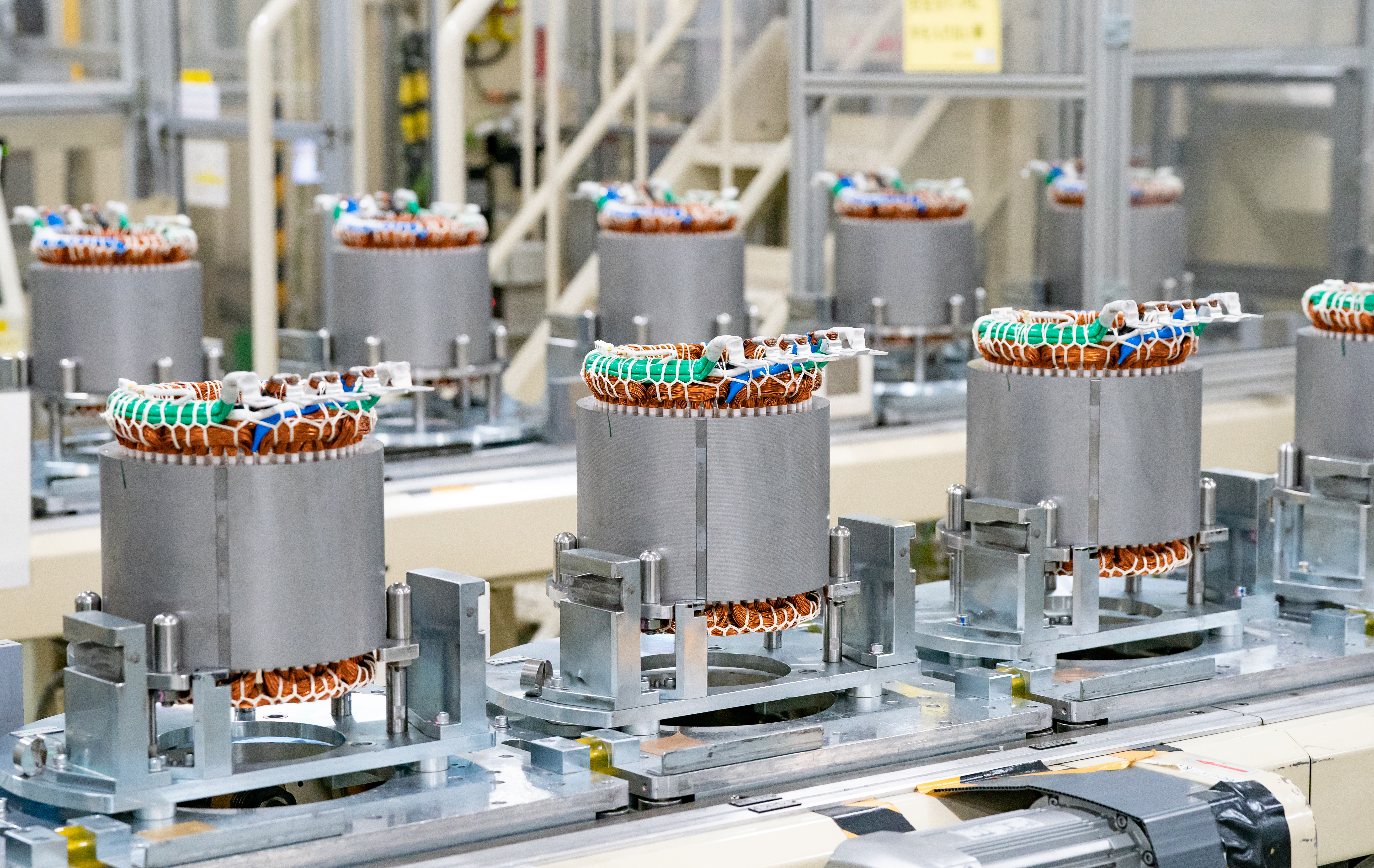

Automation Boosts Assembly of EV Motors

PC-based control and a flexible transport system increase efficiency and decrease cycle times for a stator production line.

October 11, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing