Home » grippers

Articles Tagged with ''grippers''

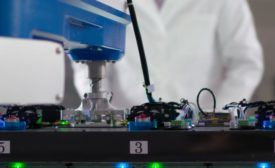

Grippers for Small Parts

Grabbing, moving and placing tiny parts is no problem—with the right gripper or cup.

December 8, 2017

advertisement

How to Choose Between Electric and Pneumatic Actuators and Grippers

March 8, 2016

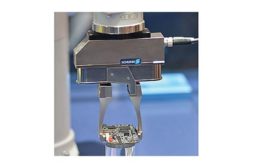

SCHUNK on Automation

SCHUNK Grippers Have Set Assembly Benchmarks for More Than 30 Years

September 30, 2013

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing