Home » flexible assembly

Articles Tagged with ''flexible assembly''

Vision-Guided Robots Improve Nut Welding

Machine vision lends flexibility to robotic welding cell

November 3, 2014

Modular Framing Systems Let Engineers Get Creative

New products enable high levels of flexibility and customization.

November 3, 2014

2014 Assembly Plant of the Year

Assembly Plant of the Year: STIHL Stays a Cut Above the Competition

Flexible assembly lines and vertical integration thrive in Virginia Beach.

October 3, 2014

Producing in Synch With Sales

Manufacturers have two opposite ways of equipping factories to respond quickly to customer demand.

August 5, 2014

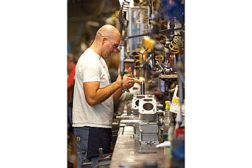

Kohler Excels at Manufacturing Small Gas Engines

Reliability in the field starts with quality on the assembly line.

June 3, 2014

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing