Home » flexible assembly

Articles Tagged with ''flexible assembly''

2017 Assembly Plant of the Year: AGCO Leads the Field With Lean Technology

Wearable devices help build better tractors in Jackson, MN.

October 4, 2017

Flexible Assembly Machine Combines Multiple Plastics Joining Processes

What if one machine could be configured to perform any friction-based welding process with a simple change of tooling?

September 12, 2017

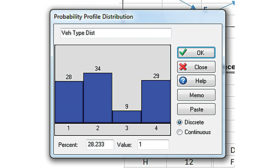

Fixed vs. Flexible Automation Systems

Both fixed and flexible technologies offer distinct advantages, but only if manufacturers optimize important operational parameters.

September 8, 2017

Robots Get Mobile

New technology enables robots to roam about the factory floor.

September 1, 2017

Lean Manufacturing Helps LED Lighting Company Compete

Continuous improvement helps Jarvis Lighting compete against low-cost rivals.

August 3, 2017

What’s New With Assembly Workstations

More than ever, workstations need to provide ergonomic benefits and design flexibility for changing production needs.

May 5, 2017

advertisement

How To Boost Employee Wellness and Lower Costs in the Workplace with Ergonomics

March 8, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing