Home » flexible assembly

Articles Tagged with ''flexible assembly''

The Industrial Internet of Things improves data collection and traceability

Read More

Automation Gives Medical Device Manufacturer a Shot in the Arm

Collaborative robots help improve productivity and reduce costs.

January 3, 2018

La-Z-Boy stays agile with lean foundation

“We probably spend as much time on our people as we do on anything.”

January 3, 2018

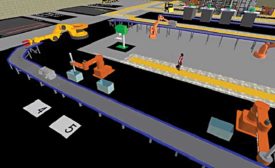

3D Sensors and Mixed-Model Assembly

Robots and 3D smart sensors are enabling automated mixed-model assembly across a wide range of industries.

November 13, 2017

Comparing Structural-Component Systems

Multiple T-slot framing, pipe-and-joint and square-tube systems let engineers get creative when building workstations, flow racks and other production structures

November 1, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing