Home » fasteners

Articles Tagged with ''fasteners''

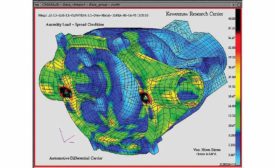

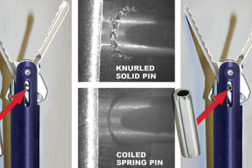

Bolts generate a lot of clamp load in a small area. That’s good for tight joints, but it can also create stress.

Read More

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing